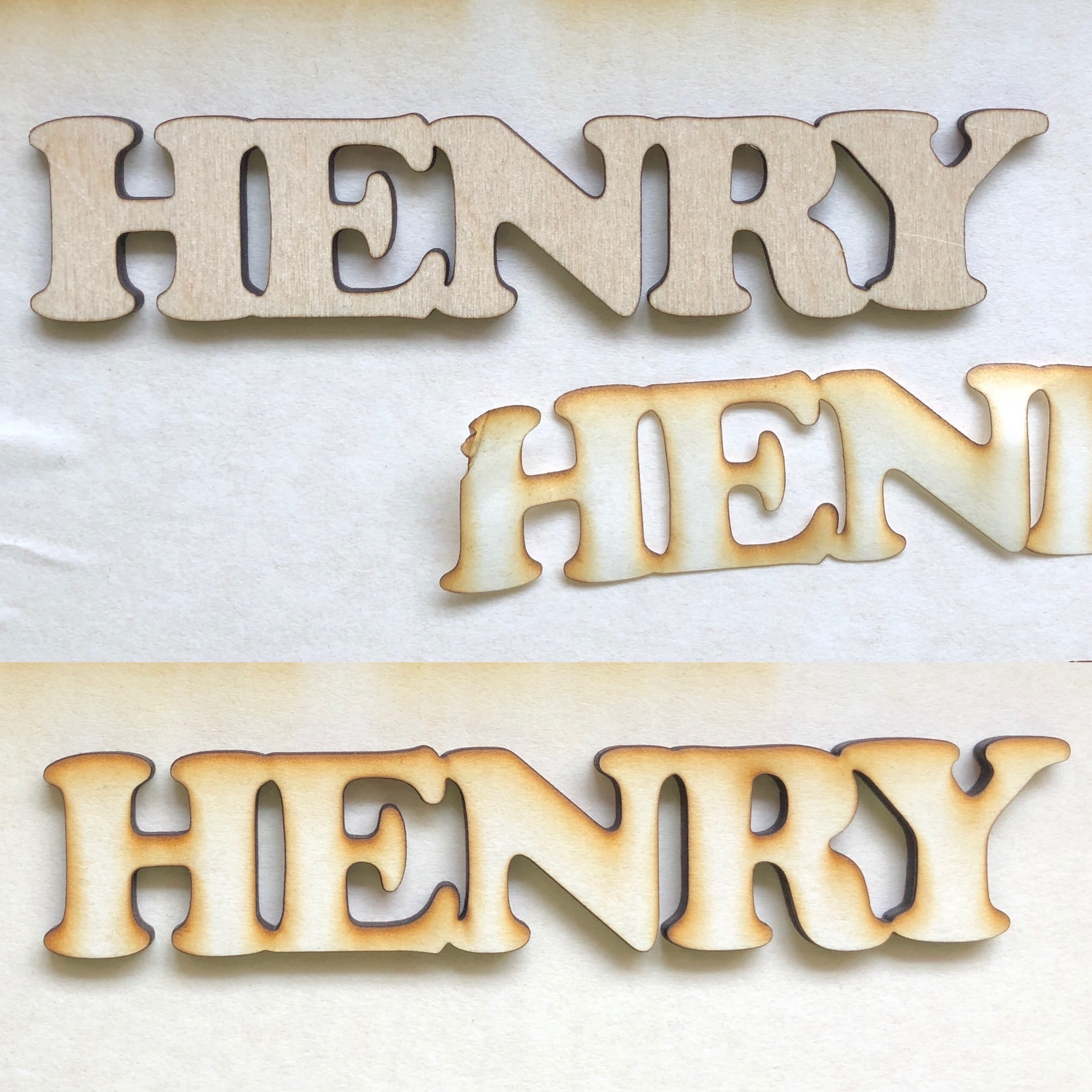

Are you getting surface scorch marks on your wood when laser cutting? Here is a tip that will help:

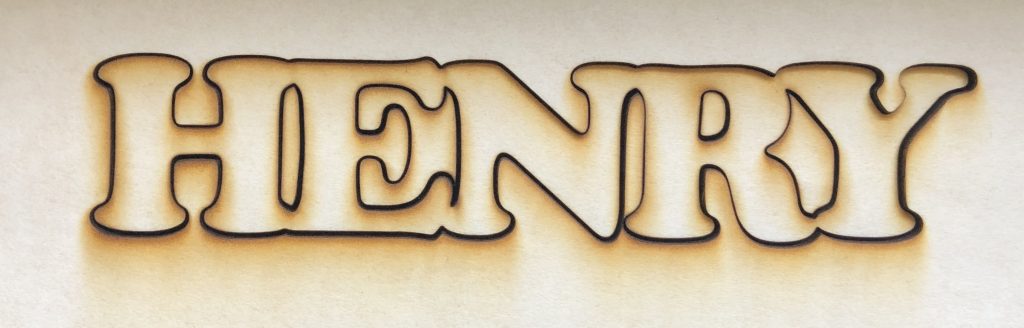

First, why are you getting this? When the laser is cutting/engraving on wood the fumes are being dragged/pulled over the material across the surface. On etching you may also get more hot debris flowing across the face towards the exhaust side thru to the vent on your laser cutter. The thicker and more combustible the material, the more noticeable this is.

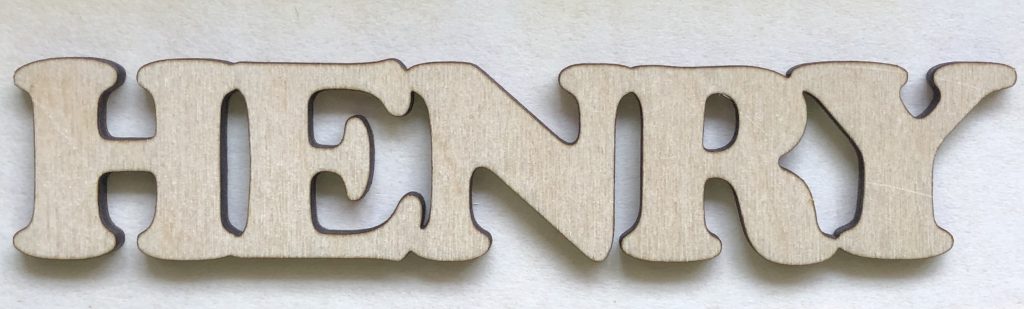

The underside of your material may also show signs of scorching due to heat build-up, previous material residue and more. So how do we stop this? We learned this trick in the vinyl cutting section at 757 Makerspace, which is to use large format paper transfer tape. We like the 12″ x 100′ foot rolls with a medium to high tack layflat adhesive (available on amazon here).

For the Glowforges, we have the factory honey-comb bed and it gets used with all kind of materials. Due to this, we always suggest using the transfer tape on at least the top surface (if one side is visible or painted) or top and bottom (when both will be handled or visible).

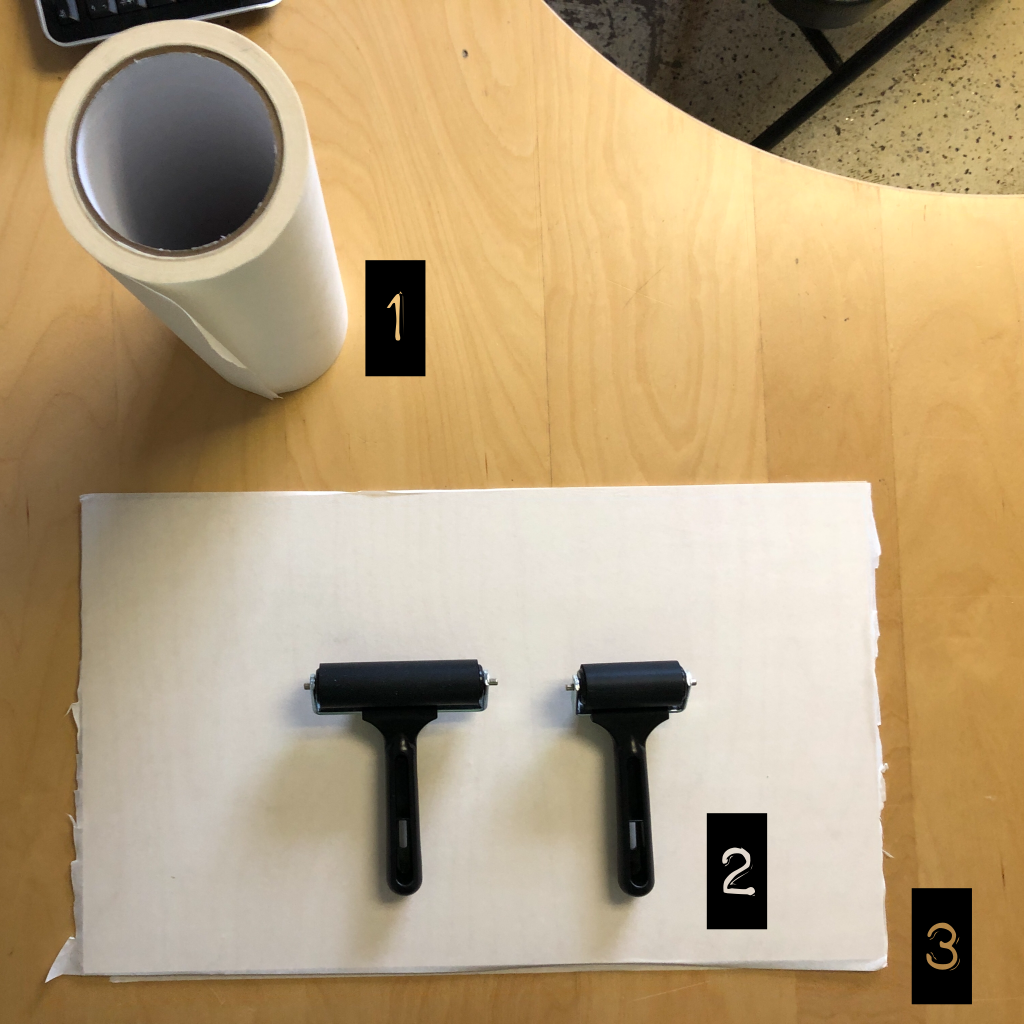

While you could just peel and stick to your material, we have had much better success without the tape coming loose or off when we use a Tape Rollers (available on amazon here). After cutting you will need to peel off the backing to reveal the clean material surface underneath.

That’s our tip and members can find this material and tools in our laser studio available to use on their next project.

2. Tape Rollers (3.8 inch, 2.2 inch)

3. 1/8″ Baltic Birch – Available locally from our friends at Yukon Lumber 520 W. 22nd Street, Norfolk, Virginia 23517 USA